Your furnace is vital to your home, keeping you warm during the chilly winter months. One crucial component often goes unnoticed: the furnace inducer motor. This small but mighty motor ensures your furnace operates safely and efficiently.

In this article, we will walk you through all the essential information about furnace inducer motors, covering their function, operation, potential issues, and replaceability.

Keep reading to learn more!

Understanding the Furnace Inducer Motor

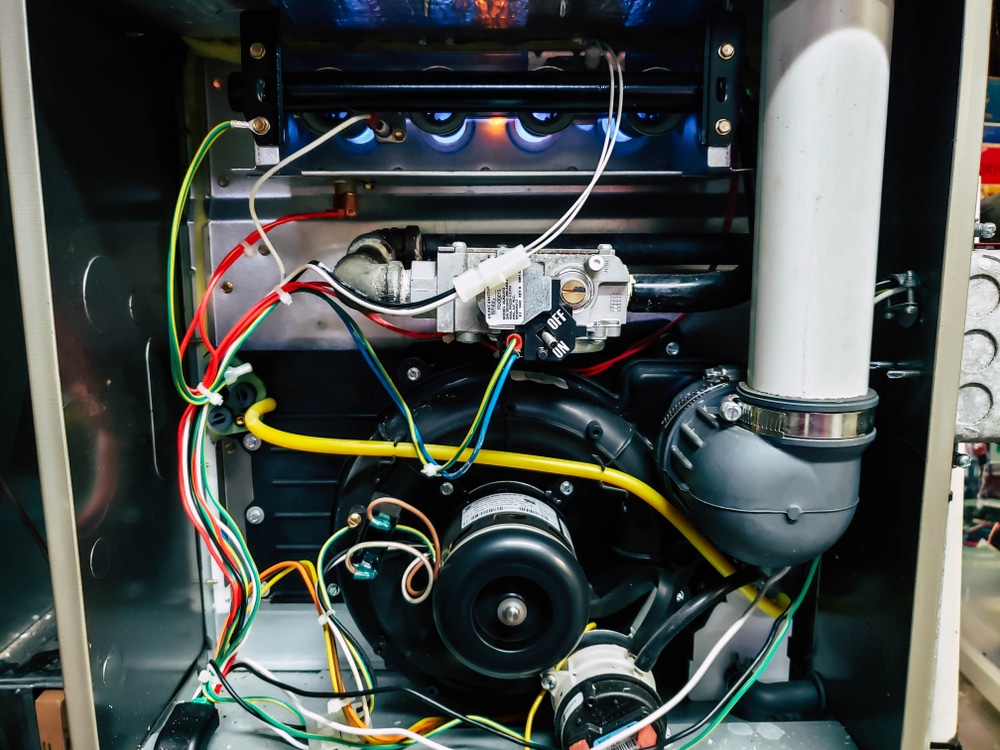

A furnace inducer motor, often called an exhaust inducer motor, draft inducer motor, or ventor motor is a critical component of your home’s heating system. Its primary function is to assist in removing combustion gases from your furnace, ensuring that they are safely expelled from your home.

This motor is typically found near the burner assembly of your furnace. It works with the furnace’s venting system to create a draft that pulls combustion gases, such as carbon monoxide, away from the heat exchanger and safely vents them outside. In essence, it plays a crucial role in maintaining the safety of your heating system.

How do Inducer Motors Work?

Understanding the inner workings of a furnace inducer motor is essential to appreciate its significance fully. These motors operate using a simple yet effective principle. Let’s delve deeper into the intricacies of how inducer motors function.

1. Activation and Control

When your furnace is activated, the control board signals the inducer motor to start running. This initial step is crucial in initiating the entire heating process. The control board ensures that the motor operates in harmony with the furnace’s heating cycle, allowing for a seamless and controlled operation.

2. Fan Mechanism

At the heart of the inducer motor is a powerful fan. This fan is responsible for drawing air into the furnace’s combustion chamber. The fan’s design is such that it creates a specific airflow pattern, directing air exactly where it’s needed for efficient combustion.

3. Air Circulation

As the fan begins to spin, it pulls air into the combustion chamber. This influx of fresh air plays a pivotal role in facilitating the combustion process. Oxygen is essential for the furnace’s combustion of natural gas or other fuel sources. The inducer motor optimizes combustion by ensuring a steady air supply, leading to efficient and clean-burning fuel.

4. Creating Negative Pressure

One of the critical functions of the inducer motor is to create a negative pressure environment within the combustion chamber. This negative pressure serves a critical safety purpose. It ensures that combustion gases, including potentially harmful carbon monoxide, are drawn away from the heat exchanger and other sensitive components.

5. Safe Gas Venting

The inducer motor maintains this negative pressure, allowing combustion gases to flow smoothly out of the furnace. These gases are safely vented outside your home through the furnace’s venting system. This process is essential for preventing the buildup of dangerous gases inside your living space.

6. Energy Efficiency

Beyond safety, the inducer motor also contributes to the energy efficiency of your heating system. Optimizing the combustion process and ensuring the efficient removal of combustion byproducts help your furnace operate at peak performance. This not only reduces energy consumption but also lowers your heating bills.

7. Synchronization with Other Components

The inducer motor doesn’t work in isolation. It is synchronized with other furnace components, including the gas valve and the ignition system. This coordination ensures that fuel is introduced into the combustion chamber at the right moment and ignited correctly, leading to consistent and reliable heating.

8. Automatic Shutoff

Modern furnace systems are equipped with safety features that automatically shut down the inducer motor and the furnace itself if any issues are detected. This includes scenarios such as a blocked vent or a malfunction in the motor itself. Such safety measures are in place to protect your home from potential hazards.

Can a Furnace Inducer Motor Break?

Like any mechanical component, furnace inducer motors are susceptible to wear and tear over time. Here are several factors that can lead to the breakdown of these motors:

- Dust and Debris: Accumulation of dust and debris can affect the motor’s performance and efficiency.

- Age: With years of use, the motor’s bearings may wear out, causing it to become noisy or inefficient.

- Moisture: Exposure to moisture or water leaks can damage the motor and its electrical components.

- Electrical Issues: Problems with the electrical connections or control board can lead to motor failure.

- Normal Wear and Tear: Like all mechanical parts, furnace inducer motors have a limited lifespan and. will eventually need replacement.

Is this Component Replaceable?

Yes, the furnace inducer motor is replaceable, but it’s a task best left to qualified HVAC technicians.

Replacing the motor involves technical knowledge and specific tools. Moreover, proper installation is crucial to ensure the safety and efficiency of your furnace.

If you suspect that your furnace inducer motor is failing, it’s essential to call a professional HVAC technician to diagnose the issue and perform any necessary repairs or replacements. Attempting to replace it yourself may lead to further damage and potentially compromise your safety.

Why is Furnace Inducer Motor Maintenance Important?

Understanding the necessity of furnace inducer motor maintenance is crucial to ensure the longevity and efficiency of your heating system. Here, we’ll delve into four key reasons why regular maintenance should be a priority:

1. Safety Assurance

The primary reason for maintaining your furnace inducer motor is safety. This motor is pivotal in venting combustion gases, including potentially deadly carbon monoxide, out of your home. Regular maintenance ensures that there are no obstructions or defects that could compromise this critical safety function. By preventing carbon monoxide leaks, you safeguard the well-being of your household.

2. Efficient Operation

Efficiency is another significant benefit of inducer motor maintenance. When the motor operates smoothly and without hindrance, it optimizes the combustion process. This efficiency not only keeps your home warm but also reduces energy consumption. A well-maintained motor can lead to noticeable cost savings on your heating bills over time.

3. Prolonged Lifespan

Like all mechanical components, furnace inducer motors have a limited lifespan. However, regular maintenance can extend this lifespan significantly. By addressing wear and tear, replacing worn parts, and keeping the motor clean, you can avoid premature motor failure. This means fewer furnace replacements and greater longevity for your heating system.

4. Preventative Maintenance

Engaging in regular maintenance is a proactive approach to furnace care. By conducting routine inspections, cleaning, and servicing, you can identify potential issues before they become major problems. Addressing minor concerns early can save you from costly repairs and unexpected breakdowns, especially if you don’t want your furnace to shut off during winter.

Conclusion

The furnace inducer motor plays a crucial role in ensuring your furnace operates safely and efficiently. Understanding its function and recognizing the signs of a failing motor can help you prevent costly repairs and keep your home warm and comfortable during winter.

While replacing the motor yourself may seem doable, it’s strongly recommended to call a qualified HVAC company to ensure the job is done right and prevent further damage.